Driving industry innovations with steel research

The Centre for Advanced Steels Research (CASR) has aligned its operating strategy to address global warming and to enable sustainable growth as well as to advance on the goals of the European Green Deal and the Carbon Negative Finland 2035. The steel industry and steel applications have the most critical role in achieving climate targets.

CASR is committed to doing high-quality fundamental steel research in close cooperation with industry, using an operating model that they have developed. They have an extensive network of industry and research partners as well as infrastructure that includes services, equipment, pilot facilities, and test laboratories.

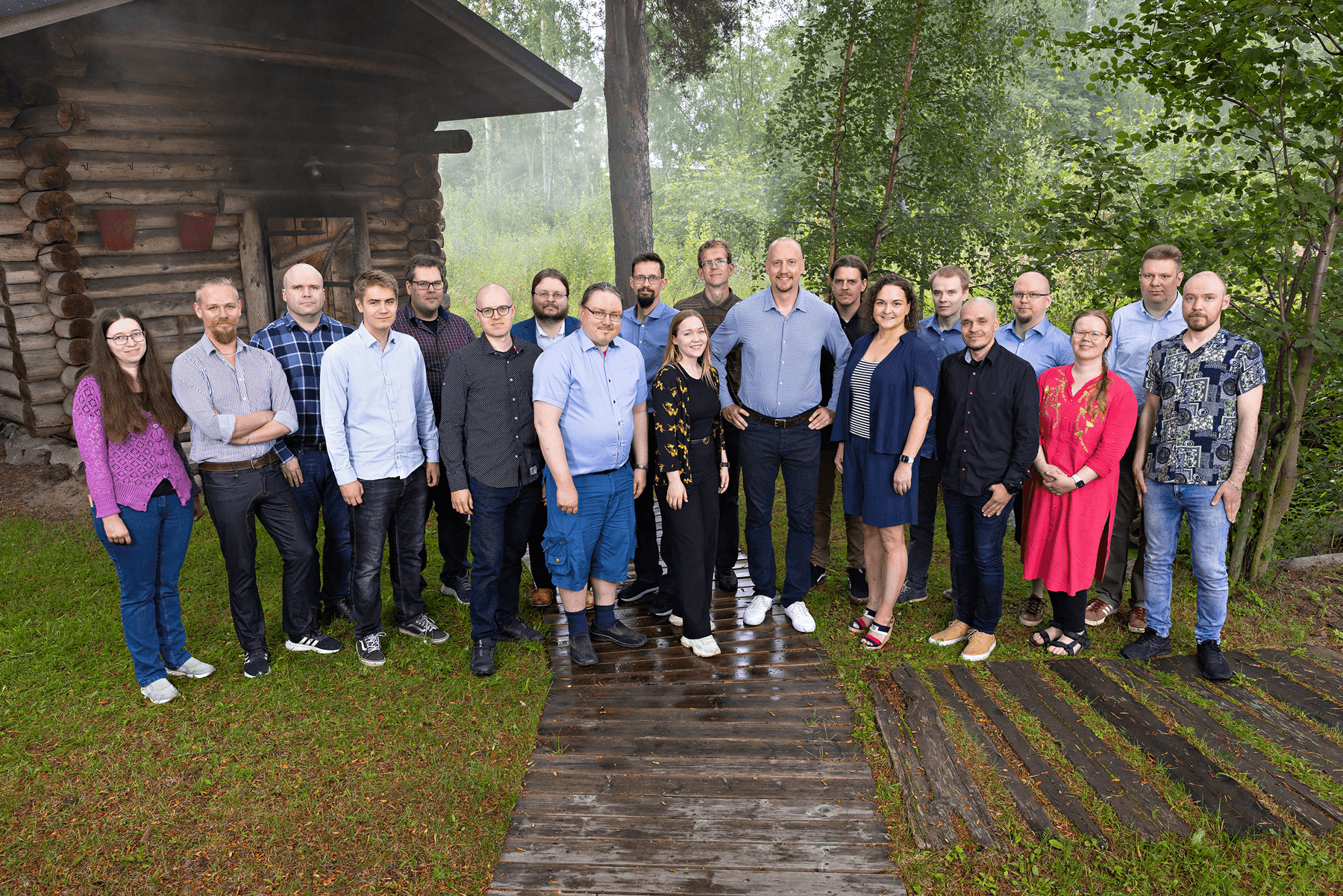

One of the research partners is Indalgo, a long-time development companion to key players in the steel industry. The company develops artificial intelligence-based optimisation, simulation, and modeling solutions for customer projects and also by taking part in research initiatives.

Collaboration spanning decades

The Head of CASR, Jukka Kömi, Professor, D. Sc. (Tech.), from the University of Oulu is very familiar with Indalgo. Before becoming the head of the research unit, he worked for a number of Finnish steel manufacturers, and his paths crossed with Indalgo’s several times over. While he used to represent the customer, he now considers them as research companions.

– The university’s role is to support industry by developing new theories and testing them out in research projects, the professor explains. – CASR functions as a platform on which new research projects are frequently launched in collaboration with steel manufacturers and other industry players.

Fossil-free steel for a carbon-neutral future

– The way steel is manufactured at the moment means factories produce more carbon dioxide than steel, illustrates Jukka. – This is something that has to change, but it requires all of the steel industry to join forces.

There are numerous initiatives underway, one of which is the HYBRIT initiative. SSAB joined forces with LKAB and Vattenfall to create the world’s first fossil-free steelmaking technology, with virtually no carbon footprint.

Making ‘clean factories’ requires massive investments, but at the same time, it is a chance to totally renew an offering with an attractive sustainability promise. Without the renewal of the steel industry, even Finland – one of the cleanest countries in the world – will be unable to meet its climate goals.

The renewal of the steel industry

According to Professor Kömi, a third of the world’s GDP is attached to the steel industry. Currently, producing a tonne of steel produces double the amount of carbon dioxide. Changing this will have a huge impact with long-lasting effects.

Indalgo has an important role in enabling the digital revolution of the steel industry. The company has developed an analytics platform, intelligent algorithms, and AI-based modeling and prediction methods that help steel producers and manufacturers to remodel processes.

Their solution, known as GreenAI, is customised to each manufacturing plant’s individual processes and delivers numerous benefits from efficiency increases to cost savings. And most importantly, it enables cleaner, more sustainable steel production.

A greener future ahead

The Finnish metals industry intends to reduce greenhouse gas emissions by nearly 70 % from the level of 2008 by 2035. It has been estimated that the use of ultrahigh-strength steels in vehicles will make them much lighter and thus further decrease emissions. Professor Kömi estimates that the use of advanced steels will help Finland cut CO2 emissions by up to 15 %. On a global scale, the potential ramifications will be enormous.

CASR’s role in the change is scientific and collaborative. One of the initiatives that also involves Indalgo is virtual steelmaking and steel processing. This involves developing experimental techniques and novel modeling solutions to obtain an understanding of the physical phenomena governing steel production and properties.

Indalgo’s expertise comes into play in the development of future processes using digital twins as risk-free test environments for process and product development. This allows new designs to succeed the first time around and cuts time-to-market for innovative products. While research into virtual steelmaking continues, Indalgo’s GreenAI solution has been commercially available for years.

Dr. Tech. CEO at Indalgo